Hill-Rom Corporation is a leading global manufacturer and provider of medical technologies and related services for the health care industry. The facility located in Skaneateles was utilizing two (2) off-site accredited labs to conduct testing of their medical devices. Rather than continue to outsource the testing, the Company created enough space in the primary plant and then moved these testing labs to an internal location, providing all services under one roof.

The purpose of the labs is to test the medical equipment through simulation. The devices are “used and abused” and pushed to the max to ensure they pass all regulatory requirements and continue to operate properly under all scenarios. As a result of these new internal processes, the medical equipment is now built onsite, tested and proven onsite, and delivered to hospitals and healthcare organizations around the world. The renovated space includes:

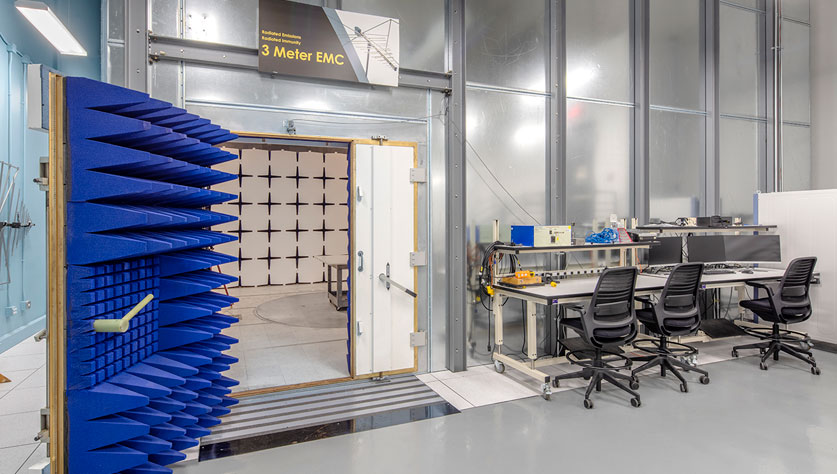

- Electro-Magnetic Compatibility (EMC) and Safety Testing – ensure the electronic or electrical device does not emit a large amount of electromagnetic interference and that the equipment functions acceptably.

- Cycle Test Area – repetitive testing of equipment to ensure it continues to function as intended.

- HALT/HASS Chamber Test Area – environmental testing (i.e. temperature, humidity, vibration) for consistency in performance and reliability.

Our team renovated the former east receiving loading docks and stock room to accommodate approximately 10,000 square feet of space needed for the new labs. Work included the removal of ceilings, duct work, heating and cooling units, electrical, fire suppression, and concrete walls. Due to the height of the EMC Test Chamber, the re-purposing of the stock room space required a 1,000-2,000 square foot high bay addition with 52’ overhead doors to replace three (3) of the original four (4) receiving docks, over the original dock apron.

$275,000

saved in project costs due to Value Engineering.